+86-519-83387581

The Rising Importance of Automatic Photoelectric Glass Tape in Industrial Systems

In today’s highly automated industrial landscape, photoelectric sensors have become essential for object detection, position tracking, sorting, and quality control. However, these sensors are only as reliable as the reflective signals they receive. This is where automatic photoelectric glass tape comes into play. Designed with advanced optical coatings, precision glass substrates, and automated lamination technologies, these tapes ensure consistently strong, stable, and directional light reflection.

As factories embrace Industry 4.0 and transition toward smart manufacturing, the demand for higher precision, faster response times, and reduced energy consumption has skyrocketed. Automatic photoelectric glass tape not only meets these technical needs but also enhances system stability in high-speed, high-demand environments such as logistics automation, semiconductor fabrication, medical testing, and autonomous warehouse operations.

High-Precision Bonding Technology: Achieving Micron-Level Control

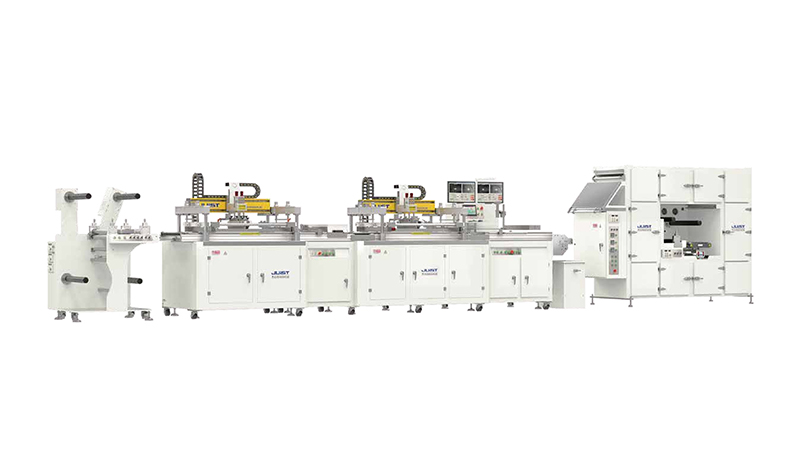

The foundation of high-performance reflective tape lies in its bonding precision. Traditional manual application methods often lead to inconsistencies in alignment, uneven adhesive layers, and reduced reflection efficiency. By contrast, automated lamination systems combine servo-driven actuators, machine vision, and real-time feedback loops to achieve micrometer-level accuracy during tape application.

Advanced systems continuously monitor the relative positioning of the glass substrate and tape, dynamically adjusting speed and pressure to maintain uniform bonding along the entire surface. This ensures that every tape is aligned perfectly, free from air gaps, and optimized for consistent reflectivity. The result is a level of accuracy that allows optical sensors to function flawlessly even in demanding, high-speed industrial environments.

Optical Principles Behind Enhanced Reflectivity and Stability

The superior performance of automatic photoelectric glass tape stems from its optical engineering. By integrating multi-layer thin-film coatings, micro-prismatic geometries, or high-index glass bead structures, these tapes are designed to maximize directional light return while minimizing energy loss.

The controlled reflection angle ensures that a greater percentage of emitted light is redirected back to the sensor, even when objects move rapidly or operate under variable lighting conditions. In applications such as high-speed scanning, laser-based positioning, and automated part alignment, these reflective properties enable precise detection without requiring excessive light intensity. This balance between high signal strength and low energy consumption makes the technology especially valuable for energy-conscious manufacturers.

Vacuum-Controlled Thermal Lamination: A Key to Reliability

Manufacturing high-performance reflective glass tape involves vacuum-controlled lamination technology, a process engineered to guarantee defect-free bonding. By removing trapped air, microscopic impurities, and surface contaminants in a low-pressure environment, this method ensures that the optical interface between the adhesive and substrate remains perfectly clean.

Equipped with real-time thermal and pressure monitoring systems, automated laminators dynamically regulate conditions throughout the process. Excessive heat risks damaging sensitive optical coatings, while insufficient bonding pressure can cause incomplete adhesion and micro-gaps that compromise reflection. Through this tight integration of process feedback, manufacturers consistently achieve uniform, durable, and optically stable products suitable for mission-critical industrial environments.

High-Performance Materials: Micro-Prisms, Coatings, and Glass Substrates

The exceptional efficiency of automatic photoelectric glass tape is rooted in material innovation. State-of-the-art designs leverage multi-layer optical coatings engineered to maximize reflectivity within specific wavelength ranges, while micro-prismatic surface structures provide controlled light directionality.

Additionally, high-quality glass substrates deliver outstanding thermal stability and mechanical strength, allowing the tape to perform reliably under extreme heat, humidity, and vibration. Some advanced products integrate UV-resistant coatings and anti-static layers, making them suitable for precision-demanding sectors such as semiconductor packaging, laser scanning, and medical diagnostic devices.

Applications in Automated Production Lines: From Detection to Sorting

Automatic photoelectric glass tape plays a crucial role in today’s automated manufacturing processes. In electronics production, it supports component positioning, solder alignment, and inspection tasks by providing stable, high-quality reflective surfaces for optical sensors. In packaging and labeling systems, it enables high-speed detection and sorting by delivering consistent reflection signals even under intense throughput conditions.

In logistics operations, where parcel and product identification must occur at speeds exceeding hundreds of items per minute, maintaining reflection consistency is critical. Traditional reflective materials often fail to keep up with these demands. By contrast, automatic photoelectric glass tape ensures strong, stable reflection over long production cycles, reducing downtime and operational errors.

Integration with Machine Vision Systems

The rise of machine vision has dramatically expanded the potential of reflective glass tape. When paired with high-resolution industrial cameras and AI-based image recognition algorithms, automatic photoelectric glass tape serves as a precise optical marker, enabling machine vision systems to perform tasks like dynamic part positioning, robotic welding calibration, and automated quality inspection.

For instance, in automotive manufacturing, robotic welding systems rely on reflective glass tape to provide stable reference points, ensuring that joints and seams are accurately aligned. By synchronizing optical reflection data with machine vision analysis, manufacturers achieve unprecedented levels of production accuracy and repeatability.

Use Cases in High-Speed Logistics and Sorting Systems

The global logistics sector increasingly depends on automatic photoelectric glass tape for high-throughput automated sorting. In e-commerce fulfillment centers, where packages must be identified, routed, and processed within milliseconds, the tape enables sensors to rapidly detect object positions and adjust conveyor routing systems in real time.

Some large-scale operations report throughput rates exceeding 20,000 packages per hour, a performance level unattainable without optimized reflection systems. By enhancing the accuracy of position detection and minimizing scanning errors, automatic photoelectric glass tape directly contributes to higher operational efficiency and reduced labor dependency.

Power Efficiency Through Optimized Reflective Performance

High-reflectivity glass tape enables sensors to operate at lower illumination levels while maintaining strong detection accuracy. This translates to 30–50% lower power consumption for optical systems, reducing energy costs and extending the lifespan of light sources and photoelectric sensors.

For large manufacturing plants and distribution hubs where thousands of sensors operate simultaneously, these efficiency gains deliver significant operational savings. Moreover, the reduction in thermal load contributes to better environmental sustainability, aligning with global efforts to reduce industrial carbon footprints.

Role in Industry 4.0 and IoT-Driven Smart Manufacturing

As Industry 4.0 technologies converge with industrial IoT platforms, automatic photoelectric glass tape will become even more critical to next-generation manufacturing ecosystems. Future smart factories will depend on real-time optical sensing combined with edge computing and AI-driven process optimization to achieve fully autonomous operations.

In this context, reflective glass tape will serve as an enabler for intelligent machine-to-machine communication. By providing consistent, high-quality optical feedback, it helps synchronize distributed systems like robotic arms, automated guided vehicles (AGVs), and predictive maintenance platforms. This integration opens the door to self-optimizing production lines capable of adapting dynamically to changing conditions.

Overcoming Technical Challenges: Durability, Compatibility, and Precision

Despite its advantages, automatic photoelectric glass tape faces several ongoing engineering challenges. Ensuring long-term durability in environments with high vibration, extreme temperatures, or abrasive contaminants requires continuous innovation in coating technology and adhesive chemistry.

Another challenge lies in compatibility. Different optical sensor types—such as laser-based detectors, CMOS vision arrays, and IR photoelectric sensors—have varying wavelength sensitivities, requiring tailored optical performance from the tape. Future research focuses on creating multi-spectral reflective surfaces that optimize performance across a wider range of sensor technologies.

Global Market Outlook and Future Opportunities

The demand for automatic photoelectric glass tape is projected to grow significantly as industries worldwide accelerate their adoption of smart manufacturing technologies. Emerging sectors such as autonomous robotics, warehouse automation, semiconductor assembly, and smart healthcare devices represent substantial growth opportunities.

Looking ahead, integration with AI-powered adaptive optics and 5G-enabled IoT networks may unlock entirely new applications, such as dynamic optical tagging, next-generation machine navigation, and fully automated predictive quality control. As manufacturing ecosystems evolve, reflective glass tape will remain a foundational component enabling precision, efficiency, and scalability.

Final Thoughts

Automatic photoelectric glass tape has rapidly evolved from a niche accessory into a core enabler of modern industrial automation. By combining advanced optical engineering, precision bonding techniques, and integration with intelligent control systems, it drives innovations in efficiency, speed, and accuracy across industries. As factories transition toward fully autonomous operations, this technology will become even more essential to the next wave of industrial transformation.