+86-519-83387581

On September 10, 2025, Changzhou JUIST Screen Printing Machinery Co., Ltd. successfully dispatched its newly developed panoramic starry roof glass screen printing line to Fuyao Group (Fuyao Glass Suzhou Plant). The successful delivery of this project marks another significant breakthrough for JUIST in the field of high-end automotive glass screen printing equipment.

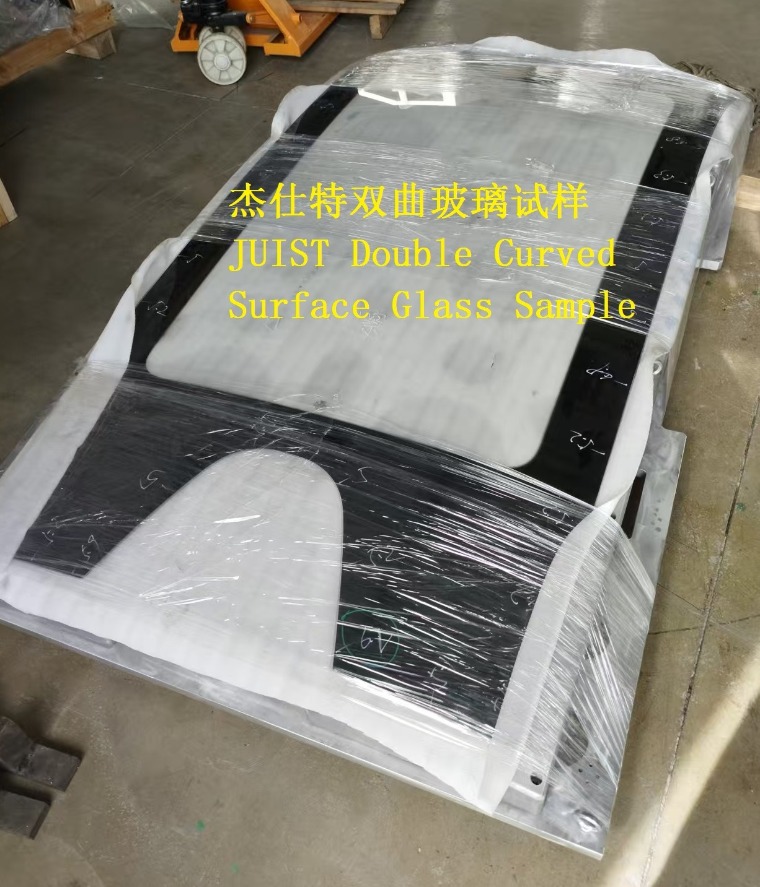

The production line measures31 meters in length, 3.5 meters in height, and 6.5 meters in width. To meet transportation requirements, the equipment was modularized and shipped in sections, carried by four 17.5-meter semi-trailer trucks to the Fuyao Suzhou facility. Prior to delivery, the line had already completed trial runs at JUIST’s plant, including the printing of over 200 star-roof glass samples across two models, fully validating its process accuracy and operational stability.

The Fully Automatic Muti-curved Glass Screen Printing Line consists of eight major sections: feeding, positioning, printing, unloading, pre-drying transfer, drying, post-drying unloading, and cooling. The entire project—from design to production—took six months, representing the dedication and expertise of JUIST’s R&D and manufacturing teams. Tailored to Fuyao’s specific star-roof glass requirements, the equipment features high-precision positioning, intelligent control, and stable high-efficiency performance, providing strong technical support for large-scale manufacturing.

This delivery not only highlights JUIST’s strong capabilities in developing comprehensive screen printing solutions for automotive glass but also demonstrates the company’s commitment to innovation and service in close cooperation with leading global automotive glass manufacturers. Looking ahead, JUIST will continue to advance its innovations in intelligent screen printing solutions, working hand-in-hand with industry partners to drive technological upgrades and high-quality development in automotive glass manufacturing.