+86-519-83387581

Core Technology and Operational Principles

As a cutting-edge hybrid material, photoelectric fiberglass derives its core appeal from the ingenious fusion of the superior mechanical properties of traditional fiberglass with modern optoelectronic technology. This material is not merely a physical layering; rather, it integrates microstructures or components with light-sensitive or light-transmitting capabilities into or onto the fiber itself. Its fundamental operational principle is based on the photoelectric conversion effect. When a light signal of a specific wavelength acts upon a sensitive region within the fiber, the material generates a corresponding electrical signal, and vice versa. This dual-directional conversion ability allows photoelectric fiberglass to function both as a high-precision optical sensor that captures changes in the external environment in real time and as an efficient data transmission medium that conveys information through complex surroundings. In automated production lines, this material can be embedded into robotic arms or conveyor belts, using changes in light signals to perceive the position, shape, or motion of objects, thereby enabling precise control and intelligent decision-making.

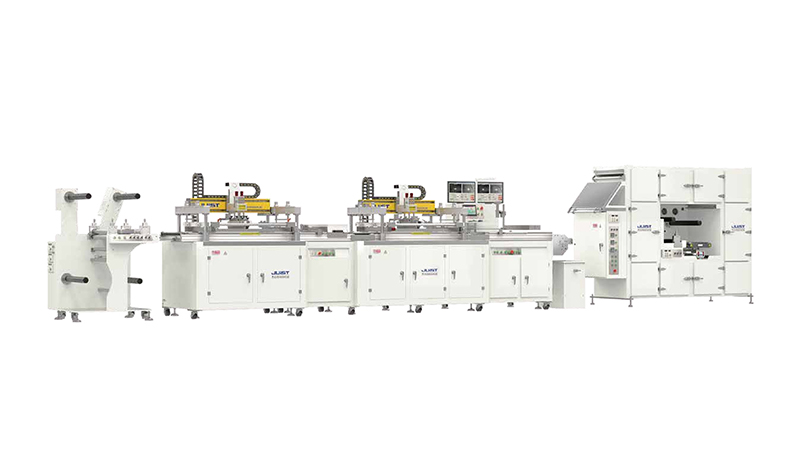

Manufacturing Processes and Automation Integration

The manufacturing of photoelectric fiberglass is a highly intricate and systematic undertaking. Particularly in its automated production flow, every single step is of paramount importance to the final product's performance. The entire process begins with the precise proportioning and melting of high-purity raw materials. At this stage, automated control systems meticulously regulate temperature and viscosity to ensure the uniformity of the molten glass. Subsequently, the molten glass is drawn into extremely fine fibers using drawing equipment. During this process, the integration of optoelectronic components is a critical technical step, demanding that the automated system embed light-sensitive materials or optical fiber preforms into the fiber's interior with micron-level precision. The entire drawing process must be conducted in a sterile, temperature- and humidity-controlled cleanroom, with a highly integrated automated control system continuously monitoring all parameters. From drawing speed and tension to finished product winding, all variables are adjusted in real time to ensure that every single fiber possesses consistent optical and mechanical properties. This level of automation integration not only vastly improves production efficiency but also effectively reduces human error, guaranteeing the stability and consistency of the product's quality.

Performance Testing and Quality Control

To ensure that photoelectric composite fiberglass can meet the rigorous demands of its applications, comprehensive performance testing and stringent quality control are non-negotiable. Performance testing is typically divided into three main areas: optical properties, mechanical strength, and electrical performance. Optical performance tests include the detection of light loss, dispersion, and signal transmission rate—metrics that directly determine its accuracy and efficiency as a sensor or transmission medium. Mechanical strength tests evaluate its tensile strength, bending resistance, and impact resistance to ensure it can withstand external stresses in real-world applications without failing. Electrical performance tests focus on its insulation, conductivity, or photoelectric conversion efficiency. These tests must be conducted in professional laboratory environments using high-precision instruments. Every product batch must pass these rigorous tests, and detailed quality records must be maintained to enable full-process traceability. This rigorous quality control system is the foundation for ensuring the reliability of photoelectric fiberglass in high-end applications.

Innovative Applications and Industry Transformation

The unique properties of photoelectric fiberglass have unlocked immense application potential across numerous high-tech fields and are quietly driving a quiet industry transformation. In the realm of smart buildings, it can be seamlessly integrated into building facades or windows to serve as an intelligent sensor for ambient light, temperature, or vibration, automatically adjusting indoor lighting and temperature based on external conditions to optimize energy management. In the aerospace industry, this material can be used to create lightweight structural components that also possess structural health monitoring capabilities. By sensing stress, strain, and micro-cracks in real time, it provides firsthand data for the safe maintenance of aircraft. Furthermore, in robotics and medical devices, photoelectric fiberglass is beginning to play an increasingly important role, used in the manufacturing of high-precision tactile sensors and minimally invasive surgical tools. The widespread adoption of this technology is not only fueling the automation and intelligent upgrading of related industries but is also opening up boundless avenues for innovation in the future of material science and engineering.