+86-519-83387581

1. High-Performance Screen Printing in Limited Factory Space

With rising labor costs and limited production floor space, manufacturers are seeking equipment that delivers higher output, lower labor dependency, and compact installation size.

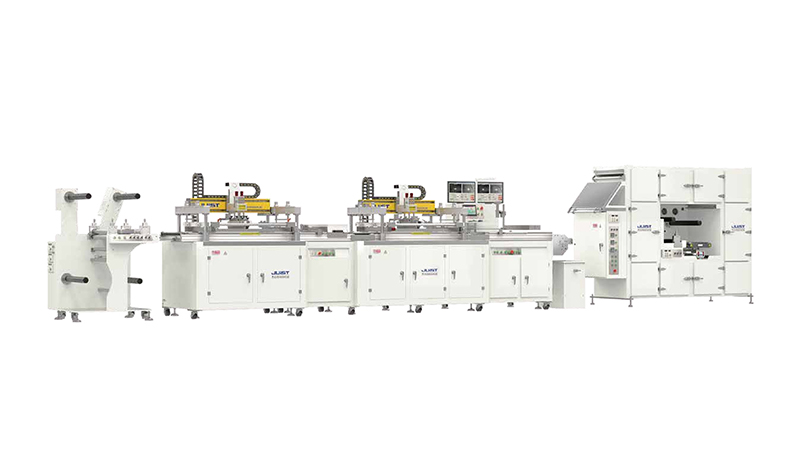

JUIST 300×400 Five-Station Rotary Screen Printing Machine is engineered specifically to meet these demands. Other sizes can be customized.

2. Fully Automated Workflow with Five Integrated Stations

The machine features a compact rotary design with five automation modules:

1) CCD Auto-Alignment Loading – High accuracy for precision printing

2) Dust Removal Station – Ensures clean surfaces and stable quality

3) High-Precision Screen Printing Station – Suitable for multiple industries

4) UV Curing Station – Fast and uniform curing

5) Auto Unloading Station – Reduces labor and increases throughput

The machine delivers an impressive output of up to 700 pcs/hour, making it ideal for mass production.

3. Reduce Labor, Save Space & Boost Productivity

The compact rotary design allows businesses to maximize production efficiency without expanding factory space.

Key advantages:

- Higher screen printing throughput

- Reduced operator requirements

- Small installation footprint

- Enhanced stability and quality consistency

- Supports automation and smart manufacturing upgrades

It is an excellent solution for companies focused on cost reduction and efficiency improvement.

4. Driven by Real Customer Needs

JUIST R&D direction is always guided by customer feedback.

We will continue developing advanced screen printing solutions featuring higher automation, greater stability, and smarter control systems — helping factories transition toward Industry 4.0.

For more information on machine specifications or customized solutions, please contact us:

Email: sales@juistmac.com

Wechat/WhatsApp: +86 18921008450