+86-519-83387581

Understanding the Manufacturing Principles of Automatic Photoelectric Fiberglass

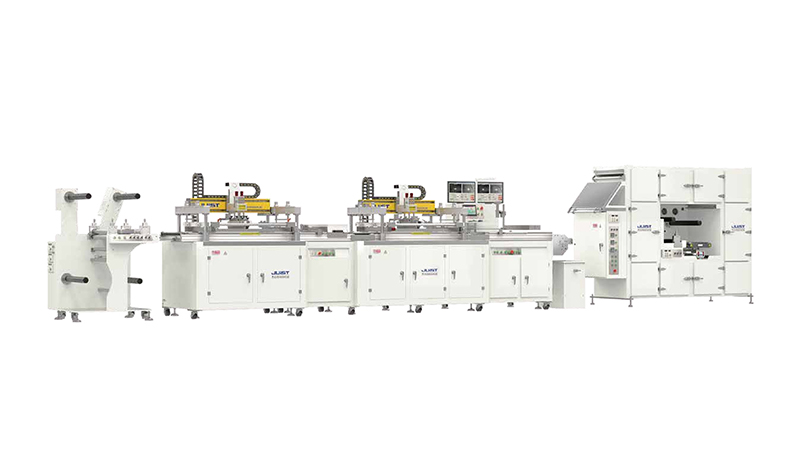

The creation of automatic photoelectric fiberglass is a sophisticated process that merges materials science with electronic engineering. It begins with the production of high-quality glass fibers, which are drawn into extremely fine strands. These fibers are renowned for their tensile strength and flexibility, forming a robust base material. The critical stage involves embedding these fibers with microscopic photovoltaic cells and light-emitting diodes. These electronic components are integrated seamlessly during the weaving or layering process, creating a composite material that is both structural and functional. A transparent conductive layer is then applied to allow for the efficient transmission of electricity throughout the panel. Finally, an intelligent control system is embedded, enabling the material to respond to environmental stimuli such as changes in light intensity or pre-programmed user commands, thereby automating its photoelectric functions.

Exploring the Core Advantages of Automatic Photoelectric Fiberglass in Construction

The integration of automatic photoelectric fiberglass into building designs offers a multitude of transformative benefits for the construction industry. This material fundamentally alters the relationship between a building's envelope and its energy consumption. By serving as an active power generator, it can significantly reduce a structure's reliance on the traditional power grid, contributing to net-zero energy goals. Simultaneously, its ability to transition between transparent and opaque states provides unparalleled control over natural lighting and solar heat gain, enhancing occupant comfort and reducing cooling costs. Beyond its functional perks, the material introduces a dynamic aesthetic element; facades and windows can change their appearance throughout the day, offering a modern and adaptive architectural expression. Its lightweight yet durable nature also allows for creative freedom in design without compromising on structural integrity.

Applications of Automatic Photoelectric Fiberglass in Smart Home Ecosystems

Automatic photoelectric fiberglass acts as a foundational element for deeply integrated smart home environments, moving beyond simple gadgetry. Imagine windows that not only generate electricity but also automatically tint to optimize indoor temperature based on the sun's position, communicating directly with the home's HVAC system. These panels can be programmed to become opaque for privacy at a set time or upon a voice command, eliminating the need for traditional blinds or curtains. Furthermore, the power generated can be used to run low-voltage devices within the home, such as sensors, smart locks, and ambient lighting systems, creating a self-sustaining loop. This seamless integration means the building itself becomes an interactive, energy-aware entity that proactively manages resources to maximize efficiency and comfort for the residents.

Assessing the Durability and Maintenance Needs of Automatic Photoelectric Fiberglass Panels

When considering the long-term viability of any building material, its resilience and upkeep are paramount. Automatic photoelectric fiberglass is engineered for exceptional durability, with the glass fiber core providing excellent resistance to corrosion, weathering, and physical impact. The embedded electronic components are encapsulated with protective coatings that shield them from moisture, UV degradation, and temperature fluctuations. In terms of maintenance, the surface is typically easy to clean, similar to conventional glass, requiring only periodic wiping to maintain optical clarity for both light transmission and energy generation. The solid-state nature of the LEDs and photovoltaic cells means there are no moving parts to wear out. While the electronic control systems are designed for longevity, it is advisable to have them periodically checked by a professional to ensure all automated functions and energy harvesting capabilities are performing at their peak over decades of service.

Analyzing the Long-Term Cost Efficiency of Automatic Photoelectric Fiberglass Systems

The initial investment in automatic photoelectric fiberglass is undoubtedly higher than that of conventional building materials. However, a comprehensive cost analysis reveals its significant long-term economic advantages. The primary financial benefit stems from its dual function as a building material and an on-site power plant, leading to substantial reductions in monthly electricity bills. In some cases, surplus energy can be fed back into the grid, creating a potential revenue stream. The material's intelligent management of solar heat gain translates directly into lower expenses for air conditioning during warmer months. Additionally, its dynamic privacy features can eliminate the need for purchasing and maintaining window treatments like blinds or curtains. When these ongoing savings are factored in over the lifespan of a building, the return on investment becomes compelling, positioning the technology not just as an architectural choice, but as a sound financial decision for future-proofed construction.