+86-519-83387581

UV Curing Technology: A New Paradigm for Efficiency and Environmental Protection

In today's industrial production, the pursuit of efficient and environmentally friendly curing solutions has become a common demand across many industries. Traditional curing methods, such as thermal curing, often require long curing times, consume a large amount of energy, and may produce harmful gases. However, UV (ultraviolet) curing technology, with its unique physical and chemical reaction mechanism, offers a brand-new solution to these challenges. It uses the energy of a specific wavelength of ultraviolet light to instantly trigger a chemical reaction in photosensitive materials, rapidly transforming them from a liquid to a solid state. This entire process requires almost no heating and produces very few volatile organic compounds, thus achieving the goals of high efficiency, energy saving, and environmental protection. This technology is widely used in printing, electronics, coatings, and medical fields, and is gradually changing traditional production models, becoming a key force in promoting industrial upgrades.

Exploring Core Components: The Life Cycle of LED Beads

The core performance of a UV curing machine is largely dependent on its light source—the LED beads. Unlike traditional mercury lamps, UV LED beads have a longer service life and higher energy conversion efficiency. A high-quality UV LED bead can have a lifespan of tens of thousands of hours under ideal working conditions, far exceeding traditional light sources. However, the life of the beads is not static; it is affected by various factors, such as the ambient temperature, the stability of the current, and the efficiency of the heat dissipation system. Excessive temperature can accelerate the aging of the beads, leading to light decay, which in turn affects the curing effect. Therefore, choosing equipment with an efficient heat dissipation system and a stable power driver is crucial. Proper use and regular checks can not only maximize the effective life of the beads but also ensure consistent curing quality.

Equipment Selection: Precision Matching According to Application Scenarios

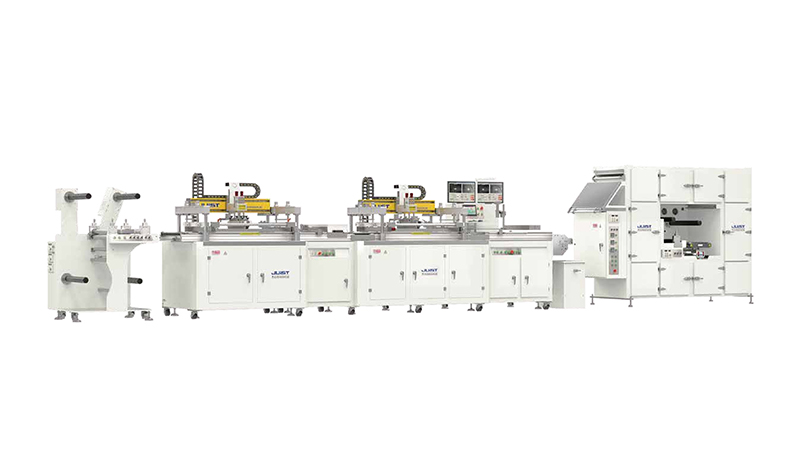

The selection of a UV curing machine is not a one-size-fits-all process; it needs to be tailored to specific application scenarios and requirements. First, the choice of power is a critical step. Different curing materials (such as adhesives, inks, coatings) have different requirements for the energy density of UV light. If the power is too low, it may lead to incomplete curing and affect product performance; if the power is too high, it may cause the material to overheat or cure unevenly. For small-scale production or laboratory applications, a small and flexible desktop UV curing machine may be sufficient. For large-volume production lines, it is necessary to choose a large conveyor-belt type curing machine that can be integrated into an automated production line. In addition, factors such as the type of light source (e.g., spot light, line light, surface light), the irradiation area, and the working distance must also be considered to ensure the equipment perfectly matches the production process for optimal curing results.

Daily Maintenance: Ensuring Efficient and Stable Operation of the Equipment

Even a UV curing machine with excellent performance requires daily maintenance and upkeep. Proper maintenance habits are key to ensuring the equipment's long-term efficient and stable operation. First, cleaning is the top priority. Regularly clean the equipment's casing, heat dissipation vents, and light source window to prevent the accumulation of dust and dirt, ensuring good heat dissipation and light transmittance. Second, regularly check the power cord, switches, and cooling fans to ensure they are working properly and to avoid equipment failure caused by aging wiring or poor heat dissipation. If the equipment's curing effect declines, it may be due to aging beads or a contaminated light window; in this case, it is necessary to replace or clean them as needed. Mastering these basic maintenance techniques can effectively extend the equipment's service life, reduce operating costs, and ensure the smooth operation of the production line.

Green Production: The Sustainable Value of UV Curing Machines

UV curing technology is not just a driver of production efficiency but also a practitioner of environmental principles. Compared to traditional curing methods, one of the greatest advantages of UV curing machines is their energy-saving and environmental characteristics. By instantly curing materials, they significantly shorten production cycles and reduce energy consumption. More importantly, the materials used in UV curing contain little or no volatile organic compounds (VOCs), which reduces environmental pollution and harm to the health of operators at the source. In a world where the "dual carbon" goal is increasingly a global consensus, choosing UV curing technology means that a company is moving towards a more sustainable production model. It not only helps companies meet increasingly strict environmental regulations but also enhances their green image, injecting powerful momentum into future sustainable development.