+86-519-83387581

In the rapid transformation of the automotive industry, new energy technologies are permeating every corner at an unprecedented pace. Among them, the integration of photovoltaic technology with automotive glass paints an exciting blueprint for future smart mobility. At its core, this technology embeds thin-film solar cells into car sunroofs, windshields, or side windows, turning what was once a mere transparent barrier into a continuous “power station.” The electricity generated by these photovoltaic glasses can provide auxiliary power to extend the vehicle’s range, supply energy to in-car devices like air conditioners and audio systems, or even charge the battery while the car is parked. To make this possible, precision is key: conductive “circuits” must be printed onto the glass surface with extreme accuracy. This core technology—photovoltaic automotive glass printing—endows ordinary glass with intelligent “nerves.”

How Are “Circuits” Drawn on Glass?

In traditional manufacturing, printing precision circuits onto non-flat glass substrates is highly challenging. Producing photovoltaic automotive glass is even more demanding: the printed conductive lines must not only conduct electricity but also withstand harsh conditions like weather exposure, temperature fluctuations, and vibrations—all while preserving the glass’s transparency and aesthetics.

Screen printing has emerged as the most mainstream and effective solution. This technique uses a fine mesh screen to precisely deposit specialized conductive pastes onto the glass surface. Every parameter, from the screen’s mesh count and tension to the刮刀 (squeegee) hardness, angle, printing pressure, and speed, requires meticulous calibration. The technology’s strength lies in its flexibility and high precision, enabling it to print complex, intricate circuit patterns tailored to different designs—ensuring conductivity and adhesion meet strict standards.

Beyond Power Generation: Versatile Applications of Printing Technology

Photovoltaics are just one key application of automotive glass printing. In modern cars, this technology has infiltrated multiple functional modules:

- Defrosting Systems: During cold winters, fog and ice on windows endanger driving safety. Printing electric defrosting lines on glass allows generated heat to quickly clear these obstacles, ensuring clear visibility for drivers.

- Integrated Antennas: Printing technology is used to create car antennas (e.g., radio, GPS) embedded in rear windows or windshields. This optimizes signal reception while keeping the exterior sleek and uncluttered.

These functions rely on the printing equipment’s precise control over line accuracy and adhesion. The post-printing curing process is particularly critical, using specific temperature profiles to bond the conductive paste tightly to the glass, forming a durable functional layer.

Efficiency and Stability: How to Choose the Right Printing Equipment?

In mass production, selecting suitable photovoltaic automotive glass printers is crucial. An excellent machine must balance high-precision printing with production efficiency and operational stability:

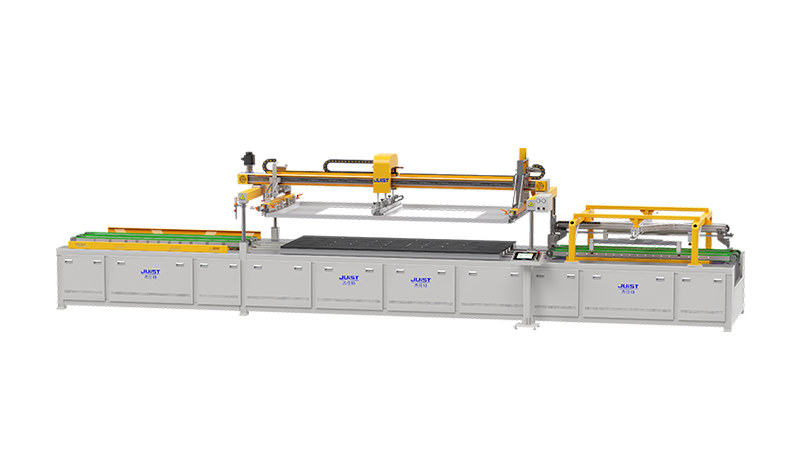

- Automation Level: A key indicator of efficiency. Fully automated workflows—from glass loading, positioning, and printing to drying and unloading—minimize manual intervention, reduce costs, and boost output.

- Printing Stability: Directly impacts product yield. The equipment’s control system should monitor and adjust parameters in real time to ensure consistent quality across every glass panel.

- Adaptability and Maintenance: When evaluating performance, consider not just precision (e.g., minimum line width, spacing) and speed, but also the machine’s ability to handle various glass sizes and curvatures, plus ease of maintenance.

Only by comprehensively assessing these factors can long-term stable production be guaranteed.

The Future Behind the Printer: Trends in Smart Manufacturing

As on-vehicle photovoltaic glass technology matures, its supporting printing equipment is evolving toward greater intelligence and integration. Future automotive glass printers will transcend their role as mere printing tools to become smart systems integrating visual recognition, data collection, and remote diagnostics.

These systems will automatically adjust printing parameters for different tasks, use vision systems to inspect quality in real time (identifying and rejecting defects), and upload production data to the cloud—supporting enterprise-wide production management and process optimization. This shift toward smart manufacturing will drastically improve the efficiency of on-vehicle photovoltaic glass production, reduce costs, and accelerate its adoption across more vehicle models.

In time, every car could feature smart glass capable of generating power, defrosting, and receiving signals—ushering in a more eco-friendly and convenient era of mobility.