+86-519-83387581

Analyzing the Precision Operational Mechanism of Roll-to-Roll Automatic Photoelectric Winding Equipment

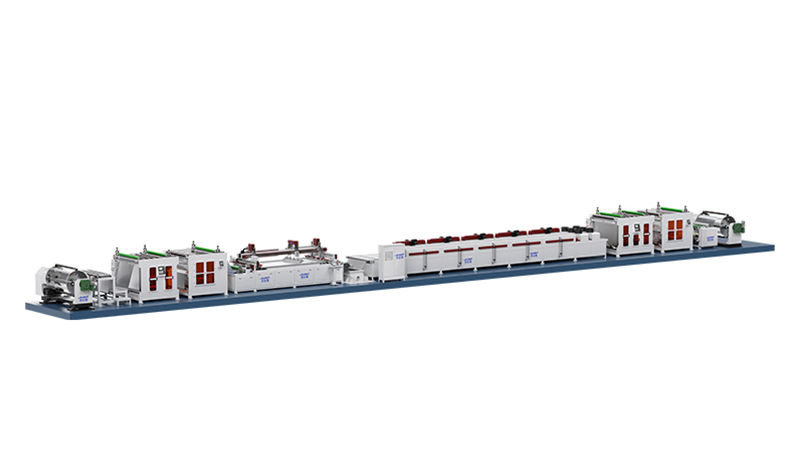

The operation of roll-to-roll automatic photoelectric winding equipment represents a meticulously orchestrated ballet of precision engineering, fundamentally reliant on photoelectric sensing technology to achieve non-destructive, high-accuracy transportation and positioning of flexible film materials. Upon initiation, the unwinding unit smoothly dispenses the substrate film, which then navigates through a series of tension-control guide rollers. These actuators function as the system's neural endpoints, perpetually monitoring and making micro-adjustments to the material's tautness, guaranteeing its unwavering stability throughout the transit process. Photoelectric sensors act as the vigilant eyes of the apparatus; they emit and receive light signals to accurately detect the material's edge position or pre-set registration marks, converting this real-time data into electrical signals fed back to the central control system. Operating as the brain, the control system processes this information rapidly and issues commands, driving precision servo motors to perform instant path correction and speed synchronization. This ensures the material is ultimately wound into a perfectly uniform roll at the rewinding unit. The entire process is characterized by a high degree of automation, securing continuous production and consistent product quality.Addressing Common Operational Challenges: Effective Diagnostics and Solutions

Despite its sophisticated design, the equipment may encounter typical issues during prolonged, continuous operation. Web guiding deviation is a relatively frequent malfunction, often stemming from contaminated sensor lenses, sensitivity drift, or misalignment of the mechanical guide rollers. Operators must routinely clean the sensors, recalibrate their detection baseline, and inspect the alignment of all guide rollers. Tension fluctuation presents another significant concern, as unstable tension can cause material wrinkling or stretching. The root cause might be the performance degradation of pneumatic or magnetic powder brakes/clutches, or a failure in the tension sensor's feedback. Systematic inspection and calibration of these execution and sensing components are required during maintenance. Improper winding, which affects product aesthetics and can lead to material waste, is often related to excessive radial runout of the rewinding shaft or wear in transmission parts. Implementing a regular preventive maintenance schedule, replacing worn components, and ensuring the dynamic balance of all rotating elements are crucial steps to prevent such issues.Maximizing Equipment Potential to Enhance Overall Production Line Output

Unlocking the full productive capacity of roll-to-roll automatic photoelectric winding equipment necessitates a dual approach focusing on process optimization and system integration. Deep optimization of operational parameters—such as precisely setting the tension gradient between unwinding and rewinding based on material characteristics, matching the optimal line speed, and fine-tuning the response sensitivity of the photoelectric correction system—can significantly reduce material waste and setup time during startups and roll changes. Integrating the equipment into a factory's Manufacturing Execution System (MES) or IoT platform enables real-time monitoring of equipment status, production efficiency, and product quality metrics, providing invaluable data for managerial decision-making. Furthermore, specialized training for operators is paramount. Skilled technicians can perform changeovers more swiftly, identify potential problems proactively, and intervene effectively, thereby minimizing unplanned downtime and ensuring a smooth and efficient production flow.Critical Evaluation Metrics for Selecting High-Quality Roll-to-Roll Automatic Winding Equipment

Selecting a roll-to-roll automatic winding machine that meets specific production demands requires a comprehensive evaluation. Equipment stability and reliability should be the foremost priority, reflected in the choice of core components and the overall rigidity and machining precision of the mechanical structure. A robust frame and a precision transmission system form the physical foundation for long-term stable operation. The sophistication and user-friendliness of the control system are equally critical. A system featuring an intuitive Human-Machine Interface (HMI), support for multiple material recipe storage, and comprehensive diagnostic functions can significantly reduce operational complexity and enhance maintenance efficiency. The machine's compatibility and adjustable range determine its application breadth. It is essential to verify that the equipment's capabilities regarding material width, thickness range, and maximum roll diameter align with both current and future product plans. Finally, the manufacturer's technical support and after-sales service capability constitute a vital soft metric. Prompt technical response and reliable spare parts supply are indispensable for ensuring the production line continues to generate value.Exploring Innovative Application Practices of This Technology in the Flexible Electronics Field

The value of roll-to-roll automatic photoelectric winding technology is profoundly demonstrated in the realm of flexible electronics manufacturing. Here, it processes various precious flexible substrate materials, such as polyimide or transparent polyester films, with exceptional efficiency and consistency. It is integral to nearly every core process in the manufacture of flexible printed circuit boards (FPCBs)—from the precise etching of copper-clad layers to the accurate lamination of protective cover films, and finally to the winding of the finished product. Its high-precision guiding capability ensures micron-level circuit patterns remain perfectly aligned during multi-layer lamination, while stable tension control prevents fragile circuits from breaking or deforming during transport. Beyond FPCBs, this technology serves as a foundational process for manufacturing cutting-edge products like flexible displays, RFID tags, and thin-film solar cells, enabling the creation of numerous wearable devices and IoT endpoints and showcasing immense application potential.