+86-519-83387581

-

Label printing technology: the key role of two-color multi-color printing machine in brand identification and communication

Technical advantages of two-color multi-color printing machine

two-color multi-color printing machine can accurately present text, patterns and colors on labels through advanced printing technology, ensuring the readability and visual appeal of label information. Compared with single-color printing, two-color or multi-color printing can give labels a richer sense of layering and detail, making the label design more vivid and three-dimensional, effectively attracting consumers' attention. This technology is not only applicable to barcode labels and QR code labels, ensuring fast and accurate scanning and identification, but also widely used in product description labels, warning labels, promotional labels and other types to meet the market's diverse needs for label functions.Ensure the readability and durability of labels

In a fast-paced logistics and sales environment, labels must have good readability and durability. two-color multi-color printing machine use high-quality inks and special printing processes, such as UV curing technology, so that the text and patterns on the label can remain clear and non-fading even under harsh conditions (such as humidity, high temperature, friction, etc.). This durability ensures the long-term effectiveness of label information. Whether it is warehouse management, logistics tracking or consumer use, product information can be accurately identified, improving the overall efficiency of the supply chain.Support diverse materials and shapes

Different industries and products have different requirements for the materials and shapes of labels. With its wide compatibility, two-color multi-color printing machine can handle labels of various materials from paper, plastic to metal foil, as well as various label designs such as round, square, rectangular, and special shapes. This flexibility allows label production to closely fit the characteristics of the product. For example, the food industry may prefer to use waterproof and oil-proof materials, while electronic products may prefer to use anti-static and wear-resistant labels. Through precise matching, labels not only meet functional needs, but also reflect the brand's care and professionalism in details.Promote brand promotion and differentiated competition

In today's increasingly fierce brand competition, labels are not only the carrier of product information, but also the direct display of brand personality and values. The rich colors and design possibilities provided by two-color multi-color printing machine provide brands with unlimited creative space, helping brands stand out from many competitors. Through unique color matching, pattern design and personalized information presentation, labels become a bridge for brands to establish emotional connections with consumers, enhancing brand recognition and loyalty.

-

Temperature: Invisible regulator of UV curing machine speed and quality

In modern industrial production, UV curing technology is widely used in coatings, adhesives, printing inks and other fields due to its high efficiency and environmental protection. As the core equipment of this technology, the working performance of UV curing machine is directly related to production efficiency and product quality. Temperature, a seemingly ordinary physical quantity, plays a vital role in the UV curing process. Temperature not only affects the speed of UV curing machine, but also directly affects the curing quality, becoming a key factor affecting the final performance of the product.

First, let's explore the effect of temperature on the speed of UV curing machine. During the UV curing process, the temperature directly affects the chemical reaction rate of UV coating or glue. When the temperature is appropriate, the photoinitiator can absorb ultraviolet energy more efficiently, thereby accelerating the chemical reaction and making the UV coating or glue cure quickly. On the contrary, if the temperature is too low, the activity of the photoinitiator will decrease, and the efficiency of absorbing ultraviolet rays will also decrease, resulting in a slower curing speed. This not only affects production efficiency, but may also bring a series of subsequent problems due to incomplete curing.

The effect of temperature on curing quality cannot be ignored. If the temperature is too low, UV coating or glue may not be completely cured, leaving unreacted components. These unreacted components will not only reduce the strength of the cured layer, but also affect its adhesion to the substrate, causing the product to easily fall off and crack during use. Especially in some applications with high requirements for strength and adhesion, such as automotive manufacturing, electronic packaging and other fields, the problem of incomplete curing caused by too low temperature is a fatal defect.

However, the higher the temperature, the better. When the temperature is too high, although it can speed up the curing speed, it may also bring a series of negative effects. High temperature will increase the stress inside the curing material, which is easy to cause defects on the surface of the cured layer, such as cracking and deformation. These defects not only affect the appearance of the product, but also may destroy the structural integrity of the cured layer and reduce its mechanical properties. In addition, high temperature may also cause certain components in the cured layer to undergo pyrolysis or oxidation reactions, causing the cured layer to turn yellow or darken. For some products with high color requirements, this color change is unacceptable.

Therefore, in the UV curing process, controlling the temperature has become a vital task. In order to ensure the dual guarantee of curing speed and curing quality, manufacturers need to accurately set the curing temperature according to the properties of specific UV coatings or glues, as well as the use requirements of the product. This usually requires a lot of experiments and tests to derive the optimal temperature range, and strict control in the actual production process.

In addition to temperature, other parameters of the UV curing machine, such as ultraviolet intensity and irradiation time, also have an important influence on the curing speed and curing quality. Therefore, when optimizing the UV curing process, it is necessary to comprehensively consider these factors and achieve the best curing effect through scientific deployment and precise control.

-

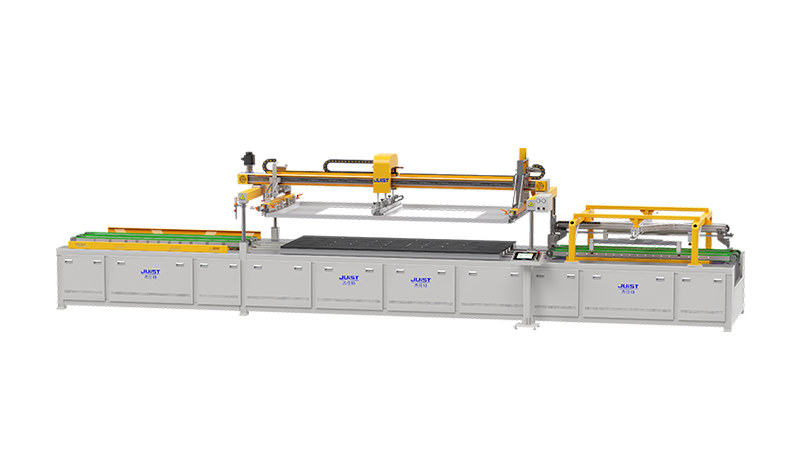

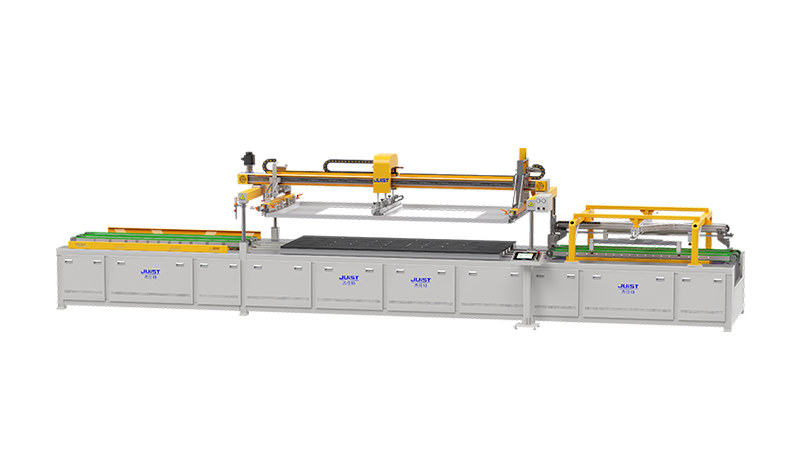

Automatic photovoltaic glass screen printing machine: key strategies to ensure stability and reliability

In today's manufacturing industry, automatic photovoltaic glass screen printing machines have become indispensable production equipment in many industries with their high efficiency and precision. However, how to ensure the stability and reliability of equipment and reduce downtime during long-term and high-intensity operation has become a major challenge facing enterprises.

Data analysis: a tool for predictive maintenance

During the operation of the automatic photovoltaic glass screen printing machine, a large amount of operation data will be generated. These data are like the "health file" of the equipment, recording every action, every adjustment and potential abnormalities of the equipment. By collecting and analyzing these data, we can gain insight into the operating status of the equipment and identify potential failure modes and causes.The first step in data analysis is data collection. This requires us to install sensors at key parts of the equipment to monitor the operating parameters of the equipment in real time, such as temperature, pressure, speed, etc. These data are transmitted to the central control system through data lines to form a huge data set. Next, using advanced data analysis tools, we can deeply mine these data and find the correlation and regularity between the data.

Through data analysis, we can identify potential hidden dangers of the equipment in advance. For example, when the data of a certain sensor fluctuates abnormally, it may indicate that the component is about to fail. At this time, we can take preventive measures in advance, such as replacing parts, adjusting parameters, etc., to avoid sudden shutdown of the equipment during the production process, causing production interruptions and losses.

Regular calibration: the cornerstone of ensuring accuracy and stability

In addition to data analysis, regular calibration is also an important means to ensure the stability and reliability of the automatic photovoltaic glass screen printing machine. During long-term operation, the sensors and control systems of the equipment may drift or deviate for various reasons, resulting in reduced measurement and control accuracy.

Regular calibration is to conduct a comprehensive inspection and adjustment of each sensor and control system of the equipment to ensure that their measurement and control accuracy meet the design requirements. During the calibration process, we will use standard calibration tools and methods to calibrate each key component of the equipment one by one. For example, for pressure sensors, we will use pressure calibrators to simulate different pressure environments to verify whether the output of the sensor is accurate; for control systems, we will enter specific instructions to verify the response speed and accuracy of the system.

Regular calibration can not only ensure the measurement and control accuracy of the equipment, but also extend the service life of the equipment. By identifying and correcting equipment deviations promptly, we can avoid excessive wear and damage to equipment caused by prolonged inaccuracy.

-

How Can Architectural Glass Express More “Emotions”?

In the modern urban jungle, towering glass curtain wall buildings, with their unique crystal-clear beauty, define the contours of cities. However, for a long time, the aesthetic expression of architectural glass has been relatively limited, relying mainly on traditional processes such as screen printing, lamination, or coating. While these methods can achieve basic patterns and color effects, they often fall short in terms of pattern complexity, color richness, and personalized customization. Traditional screen printing requires expensive mesh plates, making small-batch, multi-variety production costly and time-consuming. Lamination or coating processes, though capable of providing some basic decorative effects, also have limitations in detailing patterns.

With technological advancements, a new solution is quietly changing this landscape—digital glass printing technology. This technology is like giving glass a “paintbrush,” allowing architects and designers to unleash their creativity on the transparent canvas of glass with unprecedented freedom. It transforms architectural glass from a mere transparent body into an artistic, personalized building facade.

Beyond Patterns: The Value of Glass Printing Technology

The charm of digital glass printing technology extends far beyond simple pattern display. It is an advanced means of perfectly integrating functionality with aesthetics. By using ceramic inks for printing, these inks fuse with the glass surface after high-temperature sintering, forming a durable colored layer. These layers can not only create any pattern from monochrome to full color but also print visual textures with gradients, translucency, or even three-dimensional effects as needed.

More importantly, these inks themselves are functional. For example, printing specific patterns or dot matrices on the glass surface can effectively control sunlight transmission, reduce indoor glare, and block part of solar radiant heat from entering the room, thereby achieving energy-saving and heat-insulating effects. This seamless integration of functionality and decoration makes architectural glass more than just a medium separating indoor and outdoor spaces; it becomes an important component in enhancing building performance and improving living comfort.

Large Size, High Precision: Challenges and Breakthroughs

In the construction engineering field, glass curtain walls often require giant glass panels several meters or even over ten meters long. This poses a huge challenge for any printing equipment. Traditional digital printing devices are often unable to meet such large-scale printing needs. To address this, specialized architectural glass printing equipment has emerged. These devices feature ultra-long printing platforms and precise motion control systems, ensuring high-precision pattern printing on oversized glass panels.

However, challenges are not limited to size. Printing on glass surfaces requires overcoming ink adhesion issues, ensuring that patterns remain vibrant and intact after exposure to wind, sun, and rain. To this end, manufacturers have developed special ceramic ink formulations and integrated precise temperature control systems into the equipment, ensuring that inks fuse perfectly with glass during sintering, thus endowing printed patterns with excellent durability and weather resistance.

Customization: Giving Buildings More Soul

Modern architectural design increasingly leans toward personalization and customization to highlight a building’s unique character and cultural connotations. The emergence of digital glass printing technology perfectly caters to this trend. Unlike traditional processes that require expensive plate-making fees, digital printing technology can easily realize small-batch, multi-variety production. Designers only need to complete the design draft on a computer and then directly print it onto glass, eliminating tedious plate-making steps, significantly shortening the production cycle, and reducing costs.

Whether complex geometric patterns, abstract artworks, or textures with specific cultural symbols, they can all be perfectly presented on architectural glass. This customization flexibility allows architects to break free from the constraints of traditional processes, turning whimsical ideas into reality, and endowing each building with a unique “soul,” making it a beautiful landscape in the city.

The Future Is Here: How Glass Printing Technology Reshapes the Construction Industry

As environmental awareness grows, green buildings have become the mainstream direction of industry development. Ceramic inks used in digital glass printing usually do not contain harmful volatile organic compounds (VOCs), making it a more environmentally friendly printing solution. In addition, by precisely controlling the density and transparency of printed patterns, printed glass can effectively manage solar energy, helping buildings reduce reliance on air conditioning and lighting, and further lowering energy consumption.

Looking ahead, the application potential of glass printing technology is far greater. We can foresee that this technology will deeply integrate with cutting-edge technologies such as smart buildings and the Internet of Things. For example, printing special conductive inks on glass to turn it into smart windows that display information; or printing photovoltaic cell patterns to transform glass curtain walls into energy-generating exteriors. It is certain that this technology is reshaping the design, construction, and operation modes of buildings in an unprecedented way, creating a more beautiful, intelligent, and sustainable urban environment for us.

-

How Are Patterns “Printed” on Household Appliance Glass?

Have you ever lingered in the home appliance section of a mall, captivated by elegantly designed ovens, microwaves, or refrigerators? How do their sleek glass panels retain sharp brand logos, functional button icons, and even delicate decorative patterns with such precision and durability? This is no mere sticker or spray-paint job, but the result of a highly sophisticated manufacturing process—automated glass screen printing. As home appliances evolve toward smarter, more aesthetic designs, traditional production methods struggle to meet the stringent demands of the modern market. Manual screen printing, with its low efficiency and high error rates, fails to handle large-scale, high-standard production. Thus, fully automated glass screen printing equipment has emerged, revolutionizing the manufacturing of appliance glass panels and transforming the industry from labor-intensive to technology-driven.

“Precision” and “Efficiency”: Core Advantages of Automated Screen Printing Equipment

In home appliance manufacturing, especially for pattern printing on glass panels, precision is paramount. Whether it’s temperature scales on oven doors or function icons on microwave control panels, positioning must be exact and pattrns crystal-clear. Automated screen printing equipment integrates high-precision visual positioning systems and servo control, enabling it to capture glass panel positions with millimeter-level—or even finer—printing accuracy. This not only ensures flawless pattern presentation but also lays a solid foundation for subsequent assembly and functionality.

Efficiency is another core strength. Unlike manual operations, which require multiple workers and time-consuming efforts, automated equipment operates continuously, drastically shortening per-unit production cycles and exponentially boosting overall output. This not only cuts labor costs but also allows appliance manufacturers to quickly respond to surging market demand, seizing competitive opportunities.

Smart Appliances, Smart Manufacturing: The “Hi-Tech” Look of Control Panels

In today’s consumer market, home appliances are more than mere tools—they embody design aesthetics and smart experiences. The touchscreens and control panels of smart appliances serve as the interface for human-machine interaction, and their design directly impacts user perception and operational experience. Screen printing technology endows these glass panels with vibrant patterns and functional markings.

For example, multi-color screen printing can create layered decorative designs and functional buttons on a single glass panel, enhancing the product’s texture and tech appeal. For touch-enabled glass panels, screen printing must meet even higher standards: printing conductive inks and handling insulating layers with absolute precision to ensure touch sensitivity and stability. Automated screen printing equipment is irreplaceable here, precisely controlling ink thickness, print shape, and positioning to support both visual aesthetics and functional performance.

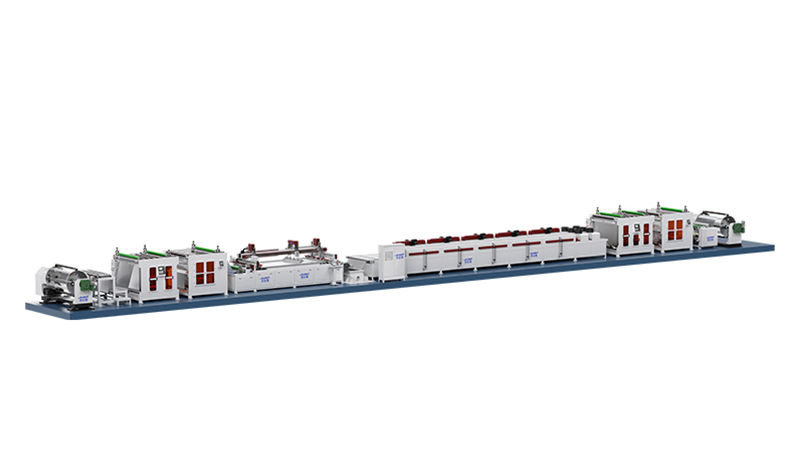

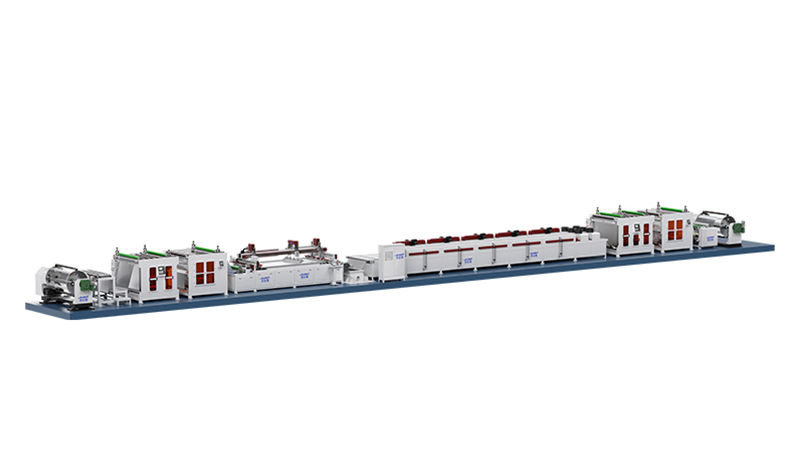

Beyond Printing: Full-Process Automation from Feeding to Curing

Modern automated glass screen printing lines encompass far more than just “printing.” They typically form a complete system integrating automatic loading/unloading, printing, drying, and material collection. When glass panels are precisely fed into the printing area via robotic arms or conveyors, high-precision screen printers spring into action. Post-printing, the panels automatically enter drying and curing ovens—a critical step that ensures ink adheres firmly to the glass, gaining properties like wear resistance, corrosion resistance, and heat resistance.

Drying and curing temperatures and durations are meticulously controlled to prevent glass deformation or ink degradation. Finally, finished glass panels are automatically collected, ready for the next production stage. This full-process automation drastically improves efficiency and product quality while reducing contamination and damage from manual handling, enabling cleaner, more efficient manufacturing.

How to Choose the Right Automated Screen Printing Equipment?

For home appliance manufacturers, selecting suitable automated screen printing equipment is key to boosting productivity.

-

Assess Equipment Performance Against Product Needs: Consider printing size, precision, speed, and multi-color capabilities. For example, manufacturers of large refrigerator doors need equipment with large-format printing capacity, while producers of high-end smart appliances should prioritize precision and color registration stability.

-

Evaluate Automation and Line Compatibility: Equipment that seamlessly integrates with existing production lines and features fully automatic loading/unloading delivers greater value.

-

Consider Customization Capabilities: As appliance designs diversify, equipment adaptable to special needs—such as irregular glass shapes or specialized inks—offers greater flexibility.

Choosing the right automated screen printing equipment is more than a machine purchase; it’s a long-term investment in future production efficiency, product quality, and market competitiveness.

-

-

When Glass Meets Photovoltaics: What Does the Future Hold for Cars?

In the rapid transformation of the automotive industry, new energy technologies are permeating every corner at an unprecedented pace. Among them, the integration of photovoltaic technology with automotive glass paints an exciting blueprint for future smart mobility. At its core, this technology embeds thin-film solar cells into car sunroofs, windshields, or side windows, turning what was once a mere transparent barrier into a continuous “power station.” The electricity generated by these photovoltaic glasses can provide auxiliary power to extend the vehicle’s range, supply energy to in-car devices like air conditioners and audio systems, or even charge the battery while the car is parked. To make this possible, precision is key: conductive “circuits” must be printed onto the glass surface with extreme accuracy. This core technology—photovoltaic automotive glass printing—endows ordinary glass with intelligent “nerves.”

How Are “Circuits” Drawn on Glass?

In traditional manufacturing, printing precision circuits onto non-flat glass substrates is highly challenging. Producing photovoltaic automotive glass is even more demanding: the printed conductive lines must not only conduct electricity but also withstand harsh conditions like weather exposure, temperature fluctuations, and vibrations—all while preserving the glass’s transparency and aesthetics.

Screen printing has emerged as the most mainstream and effective solution. This technique uses a fine mesh screen to precisely deposit specialized conductive pastes onto the glass surface. Every parameter, from the screen’s mesh count and tension to the刮刀 (squeegee) hardness, angle, printing pressure, and speed, requires meticulous calibration. The technology’s strength lies in its flexibility and high precision, enabling it to print complex, intricate circuit patterns tailored to different designs—ensuring conductivity and adhesion meet strict standards.

Beyond Power Generation: Versatile Applications of Printing Technology

Photovoltaics are just one key application of automotive glass printing. In modern cars, this technology has infiltrated multiple functional modules:

- Defrosting Systems: During cold winters, fog and ice on windows endanger driving safety. Printing electric defrosting lines on glass allows generated heat to quickly clear these obstacles, ensuring clear visibility for drivers.

- Integrated Antennas: Printing technology is used to create car antennas (e.g., radio, GPS) embedded in rear windows or windshields. This optimizes signal reception while keeping the exterior sleek and uncluttered.

These functions rely on the printing equipment’s precise control over line accuracy and adhesion. The post-printing curing process is particularly critical, using specific temperature profiles to bond the conductive paste tightly to the glass, forming a durable functional layer.

Efficiency and Stability: How to Choose the Right Printing Equipment?

In mass production, selecting suitable photovoltaic automotive glass printers is crucial. An excellent machine must balance high-precision printing with production efficiency and operational stability:

- Automation Level: A key indicator of efficiency. Fully automated workflows—from glass loading, positioning, and printing to drying and unloading—minimize manual intervention, reduce costs, and boost output.

- Printing Stability: Directly impacts product yield. The equipment’s control system should monitor and adjust parameters in real time to ensure consistent quality across every glass panel.

- Adaptability and Maintenance: When evaluating performance, consider not just precision (e.g., minimum line width, spacing) and speed, but also the machine’s ability to handle various glass sizes and curvatures, plus ease of maintenance.

Only by comprehensively assessing these factors can long-term stable production be guaranteed.

The Future Behind the Printer: Trends in Smart Manufacturing

As on-vehicle photovoltaic glass technology matures, its supporting printing equipment is evolving toward greater intelligence and integration. Future automotive glass printers will transcend their role as mere printing tools to become smart systems integrating visual recognition, data collection, and remote diagnostics.

These systems will automatically adjust printing parameters for different tasks, use vision systems to inspect quality in real time (identifying and rejecting defects), and upload production data to the cloud—supporting enterprise-wide production management and process optimization. This shift toward smart manufacturing will drastically improve the efficiency of on-vehicle photovoltaic glass production, reduce costs, and accelerate its adoption across more vehicle models.

In time, every car could feature smart glass capable of generating power, defrosting, and receiving signals—ushering in a more eco-friendly and convenient era of mobility.

-

How Does a Fully Automatic Two-Color Glass Screen Printing Machine Bring Glass “to Life”?

In modern manufacturing, glass is no longer merely a transparent material. It has been endowed with various colors, patterns, and functions, becoming a fusion of aesthetics and practicality. Whether it’s the cover glass of a mobile phone, a car windshield, or the control panel of home appliances, exquisite printing on glass plays a crucial role. However, traditional screen printing methods often require extensive manual operations, which are not only inefficient but also struggle to ensure printing precision and consistency—especially when multi-color printing is needed, where color registration becomes an arduous challenge. This approach can no longer meet the current market’s urgent demand for high precision, efficiency, and low costs. Against this backdrop, the fully automatic two-color glass screen printing machine emerged, revolutionizing traditional glass printing with its exceptional automation capabilities and precise printing technology.

Why Is a Fully Automatic Two-Color Glass Screen Printing Machine Needed?

In the past, multi-color printing on glass products typically involved multiple manual color registrations, with each step requiring manual loading, positioning, and unloading of glass. This process was time-consuming and labor-intensive, and human factors could easily lead to printing deviations and defective products. As market competition intensifies, enterprises urgently need to improve production efficiency and product quality to reduce costs and meet consumers’ increasingly strict requirements for product appearance.

Particularly in fields such as automotive glass, home appliance panels, and photovoltaic glass, the contradiction between mass production and high-precision printing has become increasingly prominent. The fully automatic two-color glass screen printing machine was developed to address these pain points. Through a complete automated system, it can complete glass loading, two-color printing, and unloading in one go, significantly shortening the production cycle, increasing productivity, and fundamentally ensuring printing stability and consistency.

Exploring the Working Principle of Fully Automatic Two-Color Screen Printing Machines

The core of a fully automatic two-color screen printing machine lies in its highly integrated automation system. The machine first uses an automatic loading and unloading device to adsorb the glass panel and accurately transport it to the printing station. Once the glass is in place, a high-precision positioning system—usually a robotic arm based on visual recognition technology—ensures the glass is in the exact printing position.

During two-color printing, the machine first prints the first color, then uses its internal conveying system to smoothly move the glass to the second printing station for the second color. The entire process requires no manual intervention, ensuring precise color registration between the two print runs. This continuous printing mode not only greatly increases printing speed but also avoids error accumulation caused by repeated positioning in traditional manual operations.

From Flat to Curved: Flexibly Tackling Different Printing Challenges

Glass is used in a variety of scenarios, from flat architectural glass to curved car rearview mirrors and mobile phone covers, with diverse shapes. This requires printing equipment to have high adaptability.

Fully automatic two-color screen printing machines excel at fine printing on flat glass, ensuring sharp pattern edges by precisely controlling squeegee pressure and printing speed. They can also easily handle curved glass printing through special fixture and print head designs. For curved printing, the equipment adjusts the printing angle and squeegee stroke to ensure ink adheres evenly to irregular surfaces while maintaining pattern integrity and color saturation. This flexible printing capability for different glass shapes allows fully automatic screen printing machines to be applied in a wider range of fields.

Smart Printing: Balancing High Precision and Efficiency

In modern manufacturing, smart technology is key to achieving high precision and efficiency. Fully automatic two-color screen printing machines are usually equipped with visual recognition and intelligent calibration systems. Before printing, high-resolution cameras scan the glass, identify its position and shape, compare it with the preset printing template, and automatically adjust the printing position to ensure each print is accurate.

If minor deviations occur during printing, the intelligent system can also make real-time compensations to prevent defective products. This intelligent, automated calibration function not only greatly improves printing precision but also reduces reliance on operators’ professional skills, thereby lowering labor costs. Through intelligent data collection and analysis, production managers can also monitor production status in real time, optimize production processes, and further improve overall efficiency.

Beyond Decoration: Application Scenarios of Fully Automatic Two-Color Screen Printing Machines

The applications of fully automatic two-color glass screen printing machines extend far beyond traditional decorative fields.

- In the home appliance industry, they are used to print control panels for refrigerators, washing machines, air conditioners, etc., enhancing product aesthetics and functionality.

- In the automotive industry, they print sunshade black edges, logos, and heating lines on car glass, ensuring driving safety and vehicle appearance.

- In construction, they print patterns on curtain wall glass to achieve both energy-saving and decorative effects.

Notably, in photovoltaic glass production, fully automatic two-color screen printing machines are used to print electrodes for solar panels—their high precision and efficiency are crucial for improving the performance of photovoltaic modules. Additionally, in medical devices and electronic equipment, the demand for fine glass printing is growing. With its excellent performance, the fully automatic two-color screen printing machine is becoming an indispensable core equipment in these industries.

-

PACK PRINT INTERNATIONAL 2025

PACK PRINT INTERNATIONAL 2025

Thematic: International Packing and Printing Exhibition for Asia

Date: September 17 to 20, 2025

Address: Bangkok International Trade & Exhibition Centre (BITEC, Hall 100–101)88 Bangna-Trad Road, Bang Na, Bangkok 10260

Juist Booth: F39

Exhibition Information of Juist:

Following our successful presence at the China International Screen Printing & Digital Printing Exhibition 2025 (Shanghai), JUIST is now heading to Bangkok for PACK PRINT INTERNATIONAL 2025 – Asia’s International Packaging and Printing Exhibition (Booth No. F39)!

At this exhibition, our mission is to introduce JUIST’s latest screen printing inspection solutions to the Southeast Asian market, including:

1) Online Inspection System: Designed for roll-to-roll screen printing. When the camera detects a defective image, the system triggers an alarm and allows operators to mark the defect, ensuring faulty prints can be efficiently eliminated during the die-cutting process.

2) Offline Inspection System: Tailored for sheet-fed screen printing. It can rapidly scan and analyze hundreds of sheets, separating qualified products from defective ones with speed and accuracy.

While printing technology has advanced with automation, quality inspection still heavily relies on manual checks—slow, inefficient, and limited for complex patterns. JUIST’s inspection solutions address these challenges by delivering higher precision, reduced labor dependence, and improved production yield.

We warmly welcome you to visit our booth and engage with the JUIST team to explore how our inspection technologies can shape the future of screen printing!

Introduction to this year's exhibition:

Organizer: Messe Düsseldorf Asia Pte Ltd, in cooperation with Exposis Co., Ltd (Thailand)

Frequency: Biennial – the 2025 edition marks its 10th anniversary

Overview:

PACK PRINT INTERNATIONAL is one of Asia’s leading trade fairs for the packaging and printing industries. Since its debut in 2007, the show has become the most important marketplace in Southeast Asia for technology providers, manufacturers, and buyers to connect, exchange ideas, and explore the latest solutions.

The 2025 edition, themed around automation, digitalization, and sustainability, will feature cutting-edge technologies and innovations across the full value chain—from packaging machinery to advanced printing solutions.

Exhibits Profile:

1) Packaging: Packaging machinery and equipment, labeling technology, materials, logistics, and storage solutions

2) Printing: Pre-press and media, printing machinery, finishing and converting technologies, digital printing, consumables, and services

Target Visitors:

The exhibition attracts professionals from a wide range of industries, including:

* Food & Beverage

* Pharmaceuticals & Cosmetics

* Automotive & Electronics

* Consumer Goods & Retail

* Logistics & E-commerce

Concurrent Event:

Held alongside CorruTec Asia 2025, a dedicated exhibition for corrugated packaging technology, offering visitors a more comprehensive experience of the packaging ecosystem.

Highlights:

1) Live technology demonstrations and product showcases

2) Industry seminars & forums covering automation, sustainable packaging, and future printing trends

3) Opportunities for networking and partnerships with leading global and regional players

-

How to Operate, Maintain, and Purchase an Automatic Photoelectric Glass Printing Machine?

How to Quickly Master the Operation Process of a Small Automatic Photoelectric Glass Printing Machine

Although the operation process of a small automatic photoelectric glass printing machine is not overly complex, it is essential to follow standardized steps to ensure printing quality and prevent equipment damage. Initially, operators must conduct a pre-operation check to verify that all components of the machine are in normal condition—this includes confirming the sensitivity of the photoelectric sensing device, the cleanliness of the printing nozzles, and the smoothness of the glass conveying track. Only after ensuring no abnormalities are found should the power be connected and the machine started. Next, equipment parameters need to be adjusted according to the size of the glass to be printed, covering aspects such as printing area positioning, ink thickness settings, and printing speed regulation. This step requires repeated calibration based on the actual specifications of the glass to ensure precise photoelectric positioning, thereby avoiding printing offset issues. Subsequently, the glass is placed stably on the conveying track, and the automatic conveying function is activated to allow the glass to slowly enter the printing area. During this phase, operators must monitor the printing process in real-time, paying close attention to whether the ink is evenly distributed and whether the pattern is complete; if any abnormalities are detected, the machine should be paused immediately for adjustments. Finally, the printed glass is transported to the drying area via the conveying track, and it can only be picked up after the ink has completely dried. Throughout the operation, it is crucial to wear protective gloves to prevent glass scratches or ink stains on the skin, while also avoiding contact with moving parts when the machine is running to ensure operational safety.

What Key Details Should Be Focused on for Daily Maintenance of Automatic Photoelectric Glass Printing Machines

Daily maintenance of automatic photoelectric glass printing machines directly impacts the equipment’s service life and printing accuracy, so several key details must be prioritized. First and foremost is cleaning: after each use, the printing nozzles should be cleaned promptly. Special cleaning agents can be used to soak the nozzles, followed by gentle brushing with a soft bristle brush to remove residual ink—this prevents nozzle clogging that could affect future use. Meanwhile, the glass conveying track should be wiped down to remove dust and ink residues, maintaining smoothness and avoiding glass jams caused by impurities. Secondly, maintenance of the photoelectric sensing device is essential. The sensitivity of the sensing probe should be checked regularly; a clean cotton cloth can be used to wipe the probe surface to remove oil and dust. If reduced sensitivity is detected, the probe angle should be adjusted or professional personnel contacted for calibration to ensure the machine can accurately identify glass positions. Furthermore, lubrication and maintenance are necessary: transmission components such as gears and bearings require monthly application of special lubricating oil to reduce wear and maintain smooth operation. However, it is important to control the amount of lubricating oil to prevent excess oil from spilling and contaminating the equipment or glass. In addition, the machine’s circuit system should be inspected regularly to check for aging or damaged wires and loose terminal connections, ensuring safe and reliable circuit connections to prevent equipment failures caused by electrical issues. Finally, it is recommended to establish a maintenance record log, detailing the time, content, and equipment status of each maintenance session. This helps identify potential problems in a timely manner and take preventive measures in advance.

Which Glass Materials Are More Suitable for Processing by Automatic Photoelectric Glass Printing Machines

Automatic photoelectric glass printing machines have specific requirements for glass materials, as not all types of glass can achieve ideal printing results—thus, it is necessary to clarify suitable glass material types. Ordinary float glass is one of the most commonly used materials; it features a flat surface, uniform thickness, and good light transmittance, allowing the photoelectric sensing device to achieve precise positioning. When printed, ink adheres strongly to this glass and does not easily peel off after drying, making it suitable for producing ordinary glass decorative paintings, glass nameplates, and similar products. Ultra-white glass is also a highly suitable material; with low impurity content and high transparency, it ensures printed patterns appear more vibrant and detailed. This makes it particularly ideal for scenarios requiring high visual quality, such as high-end furniture glass and display cabinet glass. Additionally, tempered glass can be processed by automatic photoelectric glass printing machines after special treatment, but attention must be paid to the flatness of the tempered glass surface. Slight deformation may affect printing accuracy, so flatness testing should be conducted on tempered glass before processing to ensure it meets equipment requirements. In contrast, glass materials with uneven surfaces—such as frosted glass and patterned glass—are less suitable. The surface texture of these materials disrupts the accuracy of photoelectric positioning, and ink struggles to adhere evenly to uneven surfaces, often leading to incomplete printed patterns or ink peeling. Therefore, when selecting glass materials, priority should be given to types with flat surfaces and uniform textures to guarantee printing quality.

What Should Be Prioritized When Purchasing a Low-Cost Automatic Photoelectric Glass Printing Machine

When purchasing a low-cost automatic photoelectric glass printing machine, one should not solely pursue low prices but instead consider multiple factors comprehensively to ensure the equipment’s cost-effectiveness. First, printing accuracy should be a key focus. This can be evaluated by examining parameters of the machine’s photoelectric positioning system and printing resolution. It is also advisable to conduct on-site printing tests to observe whether patterns are clear and edges are neat, avoiding quality issues caused by insufficient accuracy. Second, equipment stability is crucial. Low-cost machines may use inferior components, leading to frequent failures. Therefore, it is necessary to understand the brand of core components—such as motors, nozzles, and photoelectric sensors—and select parts with good reputations and high durability. 同时,the machine’s heat dissipation system should be checked to ensure it is well-designed, preventing performance degradation due to overheating during long-term operation. Furthermore, after-sales service is often overlooked for low-cost equipment but is essential, as problems are inevitable during use. It is important to confirm whether the supplier provides services such as installation and commissioning, maintenance, and technical consultation, as well as whether spare parts are supplied promptly—this avoids production delays caused by after-sales issues. In addition, energy consumption and floor space should be considered; the appropriate power and size of the machine should be selected based on actual production needs, ensuring it meets operational requirements while reducing long-term usage costs. Finally, it is recommended to compare products from multiple suppliers, evaluating factors such as price, performance, and after-sales service comprehensively to select the low-cost automatic photoelectric glass printing machine that best suits one’s needs.

How to Troubleshoot Common Faults of Automatic Photoelectric Glass Printing Machines

Automatic photoelectric glass printing machines may encounter various common faults during use; mastering correct troubleshooting methods enables quick restoration of equipment operation and minimizes losses. If a printed pattern is offset, the first step is to check whether the photoelectric positioning device is contaminated by dust or ink. After cleaning the sensing probe, re-calibrate the positioning parameters. If the issue persists, inspect whether the glass conveying track is deformed or jammed, adjust the track position or replace worn components to ensure smooth glass conveyance. When printing nozzles become clogged, try soaking the nozzles in a special cleaning agent for 10-15 minutes, then activate the machine’s nozzle cleaning function to flush the interior of the nozzles with the cleaning agent. For severe clogs, the nozzles can be disassembled and gently unclogged using a soft needle, but care must be taken not to damage the nozzle holes. After processing, test whether the nozzles dispense ink evenly. If the machine experiences glass conveying jams, first turn off the power, check for foreign objects blocking the conveying track, and clean them. Then, inspect whether the track bearings are worn; if the bearings do not rotate smoothly, add lubricating oil or replace the bearings. 同时,check whether the conveying motor is functioning normally—if the motor speed is abnormal, contact professional personnel to repair the motor. When the machine fails to start, first check the power connection to see if the power cord is loose or damaged. After replacing the power cord, if it still fails to start, inspect the machine’s circuit protection devices (such as fuses) and replace any blown fuses before attempting to start again. If the problem remains, troubleshoot the control board for faults. In this case, do not disassemble the machine independently; instead, contact the supplier or professional maintenance personnel for inspection and repair to avoid exacerbating the fault due to improper operation.

-

How Does Roll-to-Roll Automatic Photoelectric Winding Equipment Emerge as a Core Asset in Modern Manufacturing?

Analyzing the Precision Operational Mechanism of Roll-to-Roll Automatic Photoelectric Winding Equipment

The operation of roll-to-roll automatic photoelectric winding equipment represents a meticulously orchestrated ballet of precision engineering, fundamentally reliant on photoelectric sensing technology to achieve non-destructive, high-accuracy transportation and positioning of flexible film materials. Upon initiation, the unwinding unit smoothly dispenses the substrate film, which then navigates through a series of tension-control guide rollers. These actuators function as the system's neural endpoints, perpetually monitoring and making micro-adjustments to the material's tautness, guaranteeing its unwavering stability throughout the transit process. Photoelectric sensors act as the vigilant eyes of the apparatus; they emit and receive light signals to accurately detect the material's edge position or pre-set registration marks, converting this real-time data into electrical signals fed back to the central control system. Operating as the brain, the control system processes this information rapidly and issues commands, driving precision servo motors to perform instant path correction and speed synchronization. This ensures the material is ultimately wound into a perfectly uniform roll at the rewinding unit. The entire process is characterized by a high degree of automation, securing continuous production and consistent product quality.Addressing Common Operational Challenges: Effective Diagnostics and Solutions

Despite its sophisticated design, the equipment may encounter typical issues during prolonged, continuous operation. Web guiding deviation is a relatively frequent malfunction, often stemming from contaminated sensor lenses, sensitivity drift, or misalignment of the mechanical guide rollers. Operators must routinely clean the sensors, recalibrate their detection baseline, and inspect the alignment of all guide rollers. Tension fluctuation presents another significant concern, as unstable tension can cause material wrinkling or stretching. The root cause might be the performance degradation of pneumatic or magnetic powder brakes/clutches, or a failure in the tension sensor's feedback. Systematic inspection and calibration of these execution and sensing components are required during maintenance. Improper winding, which affects product aesthetics and can lead to material waste, is often related to excessive radial runout of the rewinding shaft or wear in transmission parts. Implementing a regular preventive maintenance schedule, replacing worn components, and ensuring the dynamic balance of all rotating elements are crucial steps to prevent such issues.Maximizing Equipment Potential to Enhance Overall Production Line Output

Unlocking the full productive capacity of roll-to-roll automatic photoelectric winding equipment necessitates a dual approach focusing on process optimization and system integration. Deep optimization of operational parameters—such as precisely setting the tension gradient between unwinding and rewinding based on material characteristics, matching the optimal line speed, and fine-tuning the response sensitivity of the photoelectric correction system—can significantly reduce material waste and setup time during startups and roll changes. Integrating the equipment into a factory's Manufacturing Execution System (MES) or IoT platform enables real-time monitoring of equipment status, production efficiency, and product quality metrics, providing invaluable data for managerial decision-making. Furthermore, specialized training for operators is paramount. Skilled technicians can perform changeovers more swiftly, identify potential problems proactively, and intervene effectively, thereby minimizing unplanned downtime and ensuring a smooth and efficient production flow.Critical Evaluation Metrics for Selecting High-Quality Roll-to-Roll Automatic Winding Equipment

Selecting a roll-to-roll automatic winding machine that meets specific production demands requires a comprehensive evaluation. Equipment stability and reliability should be the foremost priority, reflected in the choice of core components and the overall rigidity and machining precision of the mechanical structure. A robust frame and a precision transmission system form the physical foundation for long-term stable operation. The sophistication and user-friendliness of the control system are equally critical. A system featuring an intuitive Human-Machine Interface (HMI), support for multiple material recipe storage, and comprehensive diagnostic functions can significantly reduce operational complexity and enhance maintenance efficiency. The machine's compatibility and adjustable range determine its application breadth. It is essential to verify that the equipment's capabilities regarding material width, thickness range, and maximum roll diameter align with both current and future product plans. Finally, the manufacturer's technical support and after-sales service capability constitute a vital soft metric. Prompt technical response and reliable spare parts supply are indispensable for ensuring the production line continues to generate value.Exploring Innovative Application Practices of This Technology in the Flexible Electronics Field

The value of roll-to-roll automatic photoelectric winding technology is profoundly demonstrated in the realm of flexible electronics manufacturing. Here, it processes various precious flexible substrate materials, such as polyimide or transparent polyester films, with exceptional efficiency and consistency. It is integral to nearly every core process in the manufacture of flexible printed circuit boards (FPCBs)—from the precise etching of copper-clad layers to the accurate lamination of protective cover films, and finally to the winding of the finished product. Its high-precision guiding capability ensures micron-level circuit patterns remain perfectly aligned during multi-layer lamination, while stable tension control prevents fragile circuits from breaking or deforming during transport. Beyond FPCBs, this technology serves as a foundational process for manufacturing cutting-edge products like flexible displays, RFID tags, and thin-film solar cells, enabling the creation of numerous wearable devices and IoT endpoints and showcasing immense application potential.

-

Exploring the Future of Smart Materials: How Does Automatic Photoelectric Fiberglass Drive Automation and Innovation?

Core Technology and Operational Principles

As a cutting-edge hybrid material, photoelectric fiberglass derives its core appeal from the ingenious fusion of the superior mechanical properties of traditional fiberglass with modern optoelectronic technology. This material is not merely a physical layering; rather, it integrates microstructures or components with light-sensitive or light-transmitting capabilities into or onto the fiber itself. Its fundamental operational principle is based on the photoelectric conversion effect. When a light signal of a specific wavelength acts upon a sensitive region within the fiber, the material generates a corresponding electrical signal, and vice versa. This dual-directional conversion ability allows photoelectric fiberglass to function both as a high-precision optical sensor that captures changes in the external environment in real time and as an efficient data transmission medium that conveys information through complex surroundings. In automated production lines, this material can be embedded into robotic arms or conveyor belts, using changes in light signals to perceive the position, shape, or motion of objects, thereby enabling precise control and intelligent decision-making.

Manufacturing Processes and Automation Integration

The manufacturing of photoelectric fiberglass is a highly intricate and systematic undertaking. Particularly in its automated production flow, every single step is of paramount importance to the final product's performance. The entire process begins with the precise proportioning and melting of high-purity raw materials. At this stage, automated control systems meticulously regulate temperature and viscosity to ensure the uniformity of the molten glass. Subsequently, the molten glass is drawn into extremely fine fibers using drawing equipment. During this process, the integration of optoelectronic components is a critical technical step, demanding that the automated system embed light-sensitive materials or optical fiber preforms into the fiber's interior with micron-level precision. The entire drawing process must be conducted in a sterile, temperature- and humidity-controlled cleanroom, with a highly integrated automated control system continuously monitoring all parameters. From drawing speed and tension to finished product winding, all variables are adjusted in real time to ensure that every single fiber possesses consistent optical and mechanical properties. This level of automation integration not only vastly improves production efficiency but also effectively reduces human error, guaranteeing the stability and consistency of the product's quality.

Performance Testing and Quality Control

To ensure that photoelectric composite fiberglass can meet the rigorous demands of its applications, comprehensive performance testing and stringent quality control are non-negotiable. Performance testing is typically divided into three main areas: optical properties, mechanical strength, and electrical performance. Optical performance tests include the detection of light loss, dispersion, and signal transmission rate—metrics that directly determine its accuracy and efficiency as a sensor or transmission medium. Mechanical strength tests evaluate its tensile strength, bending resistance, and impact resistance to ensure it can withstand external stresses in real-world applications without failing. Electrical performance tests focus on its insulation, conductivity, or photoelectric conversion efficiency. These tests must be conducted in professional laboratory environments using high-precision instruments. Every product batch must pass these rigorous tests, and detailed quality records must be maintained to enable full-process traceability. This rigorous quality control system is the foundation for ensuring the reliability of photoelectric fiberglass in high-end applications.

Innovative Applications and Industry Transformation

The unique properties of photoelectric fiberglass have unlocked immense application potential across numerous high-tech fields and are quietly driving a quiet industry transformation. In the realm of smart buildings, it can be seamlessly integrated into building facades or windows to serve as an intelligent sensor for ambient light, temperature, or vibration, automatically adjusting indoor lighting and temperature based on external conditions to optimize energy management. In the aerospace industry, this material can be used to create lightweight structural components that also possess structural health monitoring capabilities. By sensing stress, strain, and micro-cracks in real time, it provides firsthand data for the safe maintenance of aircraft. Furthermore, in robotics and medical devices, photoelectric fiberglass is beginning to play an increasingly important role, used in the manufacturing of high-precision tactile sensors and minimally invasive surgical tools. The widespread adoption of this technology is not only fueling the automation and intelligent upgrading of related industries but is also opening up boundless avenues for innovation in the future of material science and engineering.

-

How Automatic Photoelectric Glass Tape Is Driving Precision Sensing and Intelligent Automation in Industry 4.0

The Rising Importance of Automatic Photoelectric Glass Tape in Industrial Systems

In today’s highly automated industrial landscape, photoelectric sensors have become essential for object detection, position tracking, sorting, and quality control. However, these sensors are only as reliable as the reflective signals they receive. This is where automatic photoelectric glass tape comes into play. Designed with advanced optical coatings, precision glass substrates, and automated lamination technologies, these tapes ensure consistently strong, stable, and directional light reflection.

As factories embrace Industry 4.0 and transition toward smart manufacturing, the demand for higher precision, faster response times, and reduced energy consumption has skyrocketed. Automatic photoelectric glass tape not only meets these technical needs but also enhances system stability in high-speed, high-demand environments such as logistics automation, semiconductor fabrication, medical testing, and autonomous warehouse operations.

High-Precision Bonding Technology: Achieving Micron-Level Control

The foundation of high-performance reflective tape lies in its bonding precision. Traditional manual application methods often lead to inconsistencies in alignment, uneven adhesive layers, and reduced reflection efficiency. By contrast, automated lamination systems combine servo-driven actuators, machine vision, and real-time feedback loops to achieve micrometer-level accuracy during tape application.

Advanced systems continuously monitor the relative positioning of the glass substrate and tape, dynamically adjusting speed and pressure to maintain uniform bonding along the entire surface. This ensures that every tape is aligned perfectly, free from air gaps, and optimized for consistent reflectivity. The result is a level of accuracy that allows optical sensors to function flawlessly even in demanding, high-speed industrial environments.

Optical Principles Behind Enhanced Reflectivity and Stability

The superior performance of automatic photoelectric glass tape stems from its optical engineering. By integrating multi-layer thin-film coatings, micro-prismatic geometries, or high-index glass bead structures, these tapes are designed to maximize directional light return while minimizing energy loss.

The controlled reflection angle ensures that a greater percentage of emitted light is redirected back to the sensor, even when objects move rapidly or operate under variable lighting conditions. In applications such as high-speed scanning, laser-based positioning, and automated part alignment, these reflective properties enable precise detection without requiring excessive light intensity. This balance between high signal strength and low energy consumption makes the technology especially valuable for energy-conscious manufacturers.

Vacuum-Controlled Thermal Lamination: A Key to Reliability

Manufacturing high-performance reflective glass tape involves vacuum-controlled lamination technology, a process engineered to guarantee defect-free bonding. By removing trapped air, microscopic impurities, and surface contaminants in a low-pressure environment, this method ensures that the optical interface between the adhesive and substrate remains perfectly clean.

Equipped with real-time thermal and pressure monitoring systems, automated laminators dynamically regulate conditions throughout the process. Excessive heat risks damaging sensitive optical coatings, while insufficient bonding pressure can cause incomplete adhesion and micro-gaps that compromise reflection. Through this tight integration of process feedback, manufacturers consistently achieve uniform, durable, and optically stable products suitable for mission-critical industrial environments.

High-Performance Materials: Micro-Prisms, Coatings, and Glass Substrates

The exceptional efficiency of automatic photoelectric glass tape is rooted in material innovation. State-of-the-art designs leverage multi-layer optical coatings engineered to maximize reflectivity within specific wavelength ranges, while micro-prismatic surface structures provide controlled light directionality.

Additionally, high-quality glass substrates deliver outstanding thermal stability and mechanical strength, allowing the tape to perform reliably under extreme heat, humidity, and vibration. Some advanced products integrate UV-resistant coatings and anti-static layers, making them suitable for precision-demanding sectors such as semiconductor packaging, laser scanning, and medical diagnostic devices.

Applications in Automated Production Lines: From Detection to Sorting

Automatic photoelectric glass tape plays a crucial role in today’s automated manufacturing processes. In electronics production, it supports component positioning, solder alignment, and inspection tasks by providing stable, high-quality reflective surfaces for optical sensors. In packaging and labeling systems, it enables high-speed detection and sorting by delivering consistent reflection signals even under intense throughput conditions.

In logistics operations, where parcel and product identification must occur at speeds exceeding hundreds of items per minute, maintaining reflection consistency is critical. Traditional reflective materials often fail to keep up with these demands. By contrast, automatic photoelectric glass tape ensures strong, stable reflection over long production cycles, reducing downtime and operational errors.

Integration with Machine Vision Systems

The rise of machine vision has dramatically expanded the potential of reflective glass tape. When paired with high-resolution industrial cameras and AI-based image recognition algorithms, automatic photoelectric glass tape serves as a precise optical marker, enabling machine vision systems to perform tasks like dynamic part positioning, robotic welding calibration, and automated quality inspection.

For instance, in automotive manufacturing, robotic welding systems rely on reflective glass tape to provide stable reference points, ensuring that joints and seams are accurately aligned. By synchronizing optical reflection data with machine vision analysis, manufacturers achieve unprecedented levels of production accuracy and repeatability.

Use Cases in High-Speed Logistics and Sorting Systems

The global logistics sector increasingly depends on automatic photoelectric glass tape for high-throughput automated sorting. In e-commerce fulfillment centers, where packages must be identified, routed, and processed within milliseconds, the tape enables sensors to rapidly detect object positions and adjust conveyor routing systems in real time.

Some large-scale operations report throughput rates exceeding 20,000 packages per hour, a performance level unattainable without optimized reflection systems. By enhancing the accuracy of position detection and minimizing scanning errors, automatic photoelectric glass tape directly contributes to higher operational efficiency and reduced labor dependency.

Power Efficiency Through Optimized Reflective Performance

High-reflectivity glass tape enables sensors to operate at lower illumination levels while maintaining strong detection accuracy. This translates to 30–50% lower power consumption for optical systems, reducing energy costs and extending the lifespan of light sources and photoelectric sensors.

For large manufacturing plants and distribution hubs where thousands of sensors operate simultaneously, these efficiency gains deliver significant operational savings. Moreover, the reduction in thermal load contributes to better environmental sustainability, aligning with global efforts to reduce industrial carbon footprints.

Role in Industry 4.0 and IoT-Driven Smart Manufacturing

As Industry 4.0 technologies converge with industrial IoT platforms, automatic photoelectric glass tape will become even more critical to next-generation manufacturing ecosystems. Future smart factories will depend on real-time optical sensing combined with edge computing and AI-driven process optimization to achieve fully autonomous operations.

In this context, reflective glass tape will serve as an enabler for intelligent machine-to-machine communication. By providing consistent, high-quality optical feedback, it helps synchronize distributed systems like robotic arms, automated guided vehicles (AGVs), and predictive maintenance platforms. This integration opens the door to self-optimizing production lines capable of adapting dynamically to changing conditions.

Overcoming Technical Challenges: Durability, Compatibility, and Precision

Despite its advantages, automatic photoelectric glass tape faces several ongoing engineering challenges. Ensuring long-term durability in environments with high vibration, extreme temperatures, or abrasive contaminants requires continuous innovation in coating technology and adhesive chemistry.

Another challenge lies in compatibility. Different optical sensor types—such as laser-based detectors, CMOS vision arrays, and IR photoelectric sensors—have varying wavelength sensitivities, requiring tailored optical performance from the tape. Future research focuses on creating multi-spectral reflective surfaces that optimize performance across a wider range of sensor technologies.

Global Market Outlook and Future Opportunities

The demand for automatic photoelectric glass tape is projected to grow significantly as industries worldwide accelerate their adoption of smart manufacturing technologies. Emerging sectors such as autonomous robotics, warehouse automation, semiconductor assembly, and smart healthcare devices represent substantial growth opportunities.

Looking ahead, integration with AI-powered adaptive optics and 5G-enabled IoT networks may unlock entirely new applications, such as dynamic optical tagging, next-generation machine navigation, and fully automated predictive quality control. As manufacturing ecosystems evolve, reflective glass tape will remain a foundational component enabling precision, efficiency, and scalability.

Final Thoughts

Automatic photoelectric glass tape has rapidly evolved from a niche accessory into a core enabler of modern industrial automation. By combining advanced optical engineering, precision bonding techniques, and integration with intelligent control systems, it drives innovations in efficiency, speed, and accuracy across industries. As factories transition toward fully autonomous operations, this technology will become even more essential to the next wave of industrial transformation.