+86-519-83387581

As the apparel industry continues to pursue higher standards of quality, durability and visual performance, silicone labels—known for their 3D texture, strong adhesion and excellent wash resistance—have become widely used in sportswear, outdoor apparel and various functional garments. To help apparel manufacturers improve production efficiency and product consistency, JUIST Screen Printing Machinery has fully upgraded its roll-to-roll screen printing machine and launched a new generation of “Silicone Label Screen Printing Equipment for Apparel Applications”.

Equipped with a high-precision CCD visual registration system, the new machine is engineered to solve industry challenges such as difficulty in thick-layer silicone stacking, stringent alignment requirements, and unstable production efficiency.

1. High-Precision CCD Visual Registration for Perfect Layer-to-Layer Alignment

In silicone label production, the thicker the silicone structure, the more critical precise alignment becomes. The latest JUIST machine is equipped with a self-developed CCD visual registration system. With high-speed industrial cameras and intelligent compensation algorithms, it automatically detects registration marks and performs real-time adjustments, achieving ±0.05 mm alignment accuracy.

This technology effectively eliminates manual positioning errors and ensures each silicone layer is printed with maximum precision, significantly improving structural consistency, edge cleanliness and overall yield rate.

2. 20 Silicone Layers + 4 Hot-Melt Adhesive Layers

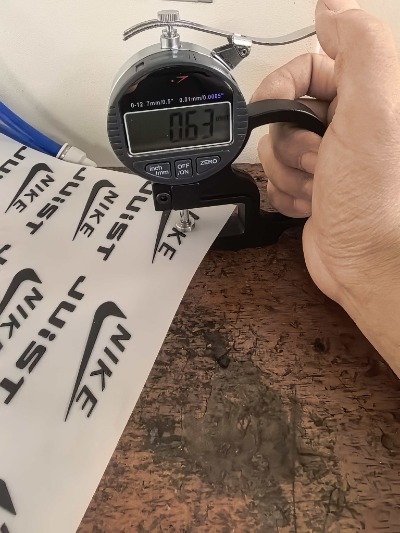

Creating 3D Silicone Labels up to 0.5 mm Thick

The new JUIST machine is specially enhanced for thick and embossed silicone applications:

* 20 layers of silicone screen printing — building a full, three-dimensional, elastic silicone structure

* 4 layers of hot-melt adhesive printing — enabling strong bonding through heat-transfer pressing, suitable for various types of fabrics

Even during high-speed operation, the machine maintains clean edges, sharp lines, smooth surfaces and uniform layering. The final silicone label can reach up to 0.5 mm thickness, delivering strong 3D effects and a solid tactile feel.

This makes it ideal for:

- Brand logos

- Sportswear silicon graphics

- Outdoor apparel elastic function labels

- All kinds of 3D silicone decorative emblems

3. An Industrial-Grade Solution for Apparel Manufacturers, Sports Brands and Accessory Suppliers

Whether producing sportswear silicone logos, outdoor function labels or premium 3D brand decorations, the new JUST silicone printing system offers a high-precision, high-speed, mass-production solution.

Key advantages include:

- Continuous roll-to-roll production for higher output and stable cycle time

- Robust and durable structure, suitable for long-term full-load operation

- Compatible with a wide range of silicone label applications and garment accessory processes

- OEM / ODM customization to support unique customer requirements

With high stability and consistent output, the system helps customers significantly enhance product value and strengthen brand competitiveness.

JUIST remains committed to technological innovation, continuously advancing the intelligence and automation of screen printing machinery to provide more comprehensive solutions for the apparel accessory industry.

Moving forward JUIST will continue to invest in R&D for silicone-related equipment, promoting smarter and more efficient production for global garment manufacturers and delivering higher quality, higher efficiency and more reliable user experiences.

For more information on machine specifications or customized solutions, please contact us:

Email: sales@juistmac.com

Wechat/WhatsApp: +86 18921008450